Do you know the different types of heat exchangers? What can specialized heat exchangers accomplish? Do heat exchangers really save energy? What problems occur with heat exchangers? Heat exchanger Flow arrangement.

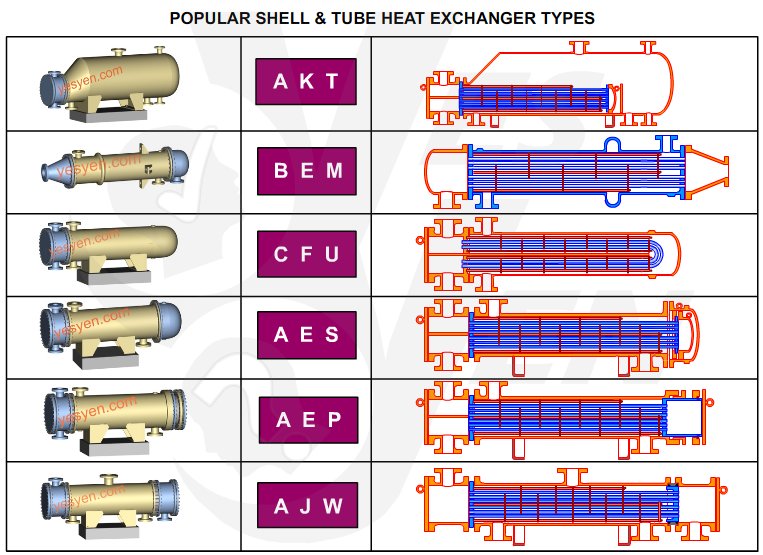

There are three primary classifications of heat exchangers according. Double pipe heat exchangers are the simplest exchangers used in industries. One of the widest uses of heat exchangers is for air conditioning. Some of the types of shell and tube heat exchangers available include helical coil heat exchangers and double pipe heat exchangers , and some of the applications include preheating , oil cooling , and steam generation. Another type of heat exchanger is the plate heat exchanger.

This is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked plate arrangement can be more effective, in a given space, than the shell and tube heat exchanger. A third type of heat exchanger is a plate and shell heat exchanger , which combines plate heat exchanger with shell and tube heat exchanger technologies. The heart of the heat exchanger contains a fully welded circular plate pack made by pressing and cutting round plates and welding them together. DIRECT CONTACT TYPE HEAT EXCHNAGER : In direct contact type heat exchanger both hot fluid.

REGENERATIVE OR STORAGE TYPE HEAT EXCHANGER : When flow of fluid is. A finned tube heat exchanger , air cooled heat exchanger (ACHE), cooler or dryer works by flowing a liquid into a series of tubes, whilst pumping gas or air around or over the pipework to cool the fluid down. Types of heat exchangers Shell and tube type. The most basic and the most common type of heat exchanger construction is the shell and tube type. This type of heat exchanger consists of a set of tubes in a container called a shell.

Indirect heat exchangers. The tubes can have various type of fins in order to provide additional surface area on the air side. Air is either sucked up through the tubes by a fan mounted above the bundle (induced draught) or blown through the tubes by a fan mounted under the bundle (forced draught). Hear What Our Customers Say: This Kind of Customer Service is Above and Beyond.

Contact An Engineer Today! Get a Full Overview of Your Market. A shell and tube heat exchanger is designed with a number of tubes placed inside a cylindrical shell. The popular design of this type of heat exchanger allows for a wide range of pressures and temperatures. What are the different types of heat exchanger?

Parallel-flow and counterflow. The fluids can also flow in perpendicular directions which is known as cross flow. The shell-and-tube heat exchanger is composed of a shell containing.

In the simplest heat exchanger,. As a heat exchanger, the adiabatic wheel acts as a mechanism for storing the heat before it is eventually released. But of the three, the counter flow heat exchanger design is the most efficient when comparing heat transfer rate per unit surface area. The most common types found in the petroleum industry are: shell and tube, double pipe, plate, and aerial coolers. Shells are made of steel, steel-lined with PTFE, FRP, CPVC, polypropylene, or different metals to meet specific application requirements.

Overall heat transfer coefficient of heat exchangers - Duration: 42:41.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.