In place of the cooling water , air-cooled chillers use ambient air to reject heat from the refrigerant in the condenser. Vapor Compressor Chillers. A compressor is used as the driving force to pump refrigerant around the system.

This type of chiller uses refrigerants to cool process fluids and spaces. An air-cooled condenser uses ambient air for cooling and condensing the refrigerant gas back to a liquid. It usually located inside the chiller or remotely, but ultimately it dissipates the heat to the atmosphere with airstream passing through the condenser coil.

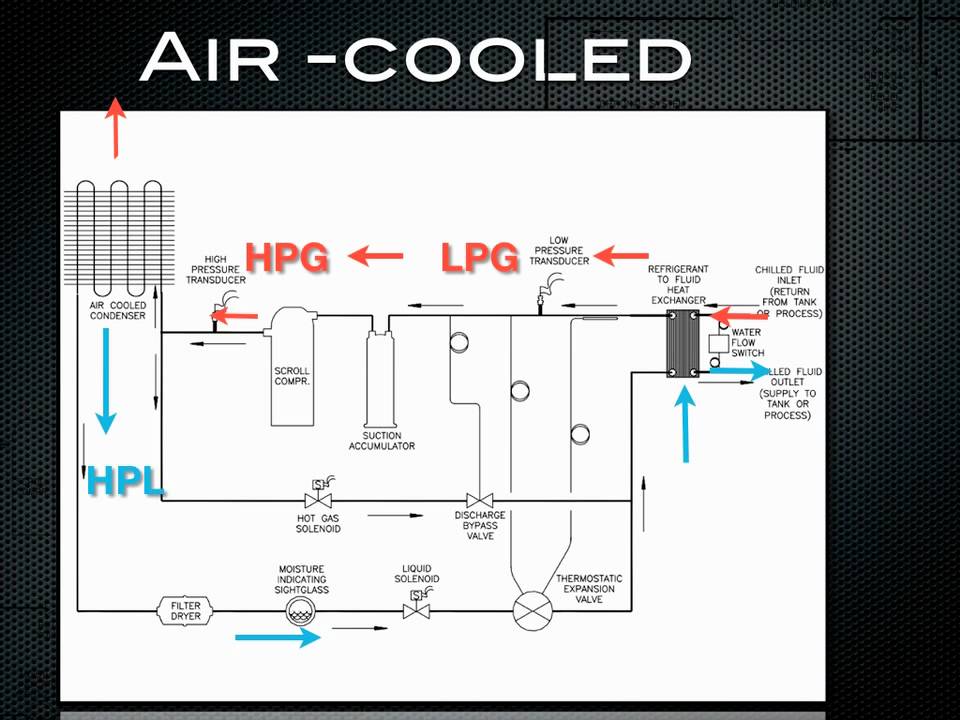

Process chillers contain a chemical compoun called a refrigerant. There are many types of refrigerant and applications depending on the temperatures required but they all work on the basic principle of compression and phase-change of the refrigerant from a liquid to a gas and back to a liquid. In the air-cooled chiller refrigeration cycle , water enters the evaporator (also known as the cooler ) and is cooled by the colder refrigerant flowing through the other circuit inside the evapo- rator. Air Cooled Chiller Working Principle Due to pressurization and cooling , the refrigerant moves in cooled tubes where its temperature is reduced. Finally, the refrigerant goes back over the chilled tubes and assimilates more heat and this makes the whole procedure become a cycle, thus providing continuous cooling from an air-cooled chiller.

An HVAC chiller works on vapor compression or vapor absorption cycle. In vapor compression cycle, refrigerant circulates in evaporator,compressor, condenser and expansion valve of a chiller. A thermodynamic process occurs in each of above chillers. Air-cooled and evaporative cooled chillers are intended for outdoor installation and operation. An air - cooled condenser uses ambient air for cooling and condensing the refrigerant gas back to a liquid.

The refrigeration circuit is the most technical part of how a chiller works. In the case of chillers, heat is taken from the fluid being chilled and transferred to the ambient air. Air - cooled chillers are chosen when it is impractical to use a cooling tower, such as when little water is available or water is highly corrosive. Fluid chillers remove heat based on the immutable principle that heat will move from a hotter source to a colder source – from the process to a conditioned fluid. They comprise two main parts called circuits – a refrigeration and a fluid circuit.

The Air - cooled Screw Chiller Unit features of compact size, low noise high energy-efficiency ratio and long service life, and is easy to operate and maintain. A wide variety of water cooled chiller working principle options are available to you, There are water cooled chiller working principle suppliers, mainly located in Asia. The top supplying country or region is China, which supply 1 of water cooled chiller working principle respectively.

There is an evaporator in a portable air - cooled chiller that can absorb the heat from chilled water. The vapor created during the absorption is taken away by the compressor where the vapor is pressurized and heated. Then, the vapor is pumped into the condenser by the compressor.

Eventually, the vapor pushes the heat out of the device. Water chiller is an integral part of an HVAC system. It removes heat from the system by cooling and dehumidifying the air. Water- cooled chiller systems have a cooling tower, thus they feature higher efficiency than air - cooled chillers. A typical air - cooled chiller working principle is shown in figure 1. The condensation occurs in the cooling coils rather than in a condenser and the heat exchange medium is air passed across the cooling coils at high speed.

Chillers function on the principle of condensing refrigerant to cool. If moisture or air leaks into the system it introduces non-condensable elements into the system that rob it of efficiency. The design conditions imposed by most water- cooled HVAC systems work very well for centrifugal chillers. The Air -Conditioning and Refrigeration Institute (ARI) provides test standards and certification for a wide range of HVAC products including centrifugal chillers.

Air - cooled condensers must be large than water- cooled units, but are not subject to freezing or water problems. Air -cooling is used when water is unavailable, expensive or chemically unsuitable. Fins, wires, or plates may be fastened to condenser tubing to increase the surface area and the ability to dispose of the heat of condensation. Chillers are a key component of air conditioning systems for large buildings.

Foundational Principles. Installation,Operation,and Maintenance Instruction for Water- cooled Screw Chiller. Air - Cooled Chillers Water- Cooled Chillers Absorption Chillers Condensers and Condensing Units Smart Connected Chillers Air Systems. Heat in the air evaporates water from the pads which are constantly re-dampened to continue the cooling process.

Then cooled , moist air is delivered into the building via a vent in the roof or wall. Because the cooling air originates outside the building, one or more large vents must exist to allow air to move from inside to outside.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.