What are the different types of heat exchangers? Do heat exchangers really save energy? Why are heat exchangers need to be run at constant pressure? What is the basic heat transfer equation?

In a regenerative heat exchanger , a heat storage medium is utilized to transfer heat between fluids. Shell and tube heat exchangers are the most common type of heat exchanger used in industrial applications. Fluidized-bed heat exchanger.

Heat Exchanger Training Program. Reasons for heat transfer include the following: 1. To heat a cooler fluid by means of a hotter fluid 2. To reduce the temperature of a hot fluid by means of a cooler fluid 3. Beside the questions of thermodynamic basics , the book addresses several important issues, such as conceptions, design, operations, fouling and cleaning of heat exchangers. It includes also storage of thermal energy and geothermal energy use, directly or by application of heat pumps.

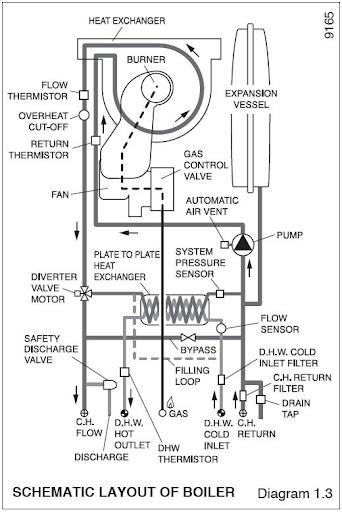

In the chemical sector, for instance, a heat exchanger ( heater ) is used to increase the temperature of an HTF, which is the heat carrier in the plant. Simply define a heater is the “point in the plant system at which the heat content (or enthalpy) of the heat transfer medium is increased. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. Prices are based on all-stainless-steel construction and will vary depending on the manufacturer.

A heat exchanger is a system used to transfer heat between two or more fluids. This course covers most exchanger types and related information in the industry. The above picture is just a screen shot, click for animated demo. The basic heat exchanger design equation can be used for a variety of types of heat exchangers, like double pipe heat exchangers or shell and tube heat exchangers. It can be used for counterflow or parallel flow.

Following are the typical steps for an air to air heat exchanger design (Please refer the above attached picture): Select heat exchanger type (i.e. decide number of passages ). There are two main types of heat exchangers. Find out the inlet and outlet temperatures ( t t Tand T2) of both the sides of the heat exchanger. Closed loops are by far the most prevalent, and circulate the same fluid between the heat pump’s main heat exchanger and the underground regime—over and over. The term exchanger applies to all equipment used to transfer heat between two streams.

However, the term is commonly used to equipment in which two process streams exchange heat with each other. The Air-cooled heat exchanger is a device for rejecting heat from a fluid or gas directly to ambient air. When cooling both fluids and gases, there are two sources readily available, with a relatively low cost, to transfer heat to….

In a heat exchanger unit neither a hot stream can be cooled below cold stream supply temperature nor a cold stream can be heated to a temperature more than the supply temperature of hot stream. In practice the hot stream can only be cooled to a temperature defined by the ‘temperature approach’ of the heat exchanger. Wide Selection of Weil-McLain HVAC Equipment.

Free Shipping Over $200.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.